UBQ Materials Masters the Alchemy of Turning Garbage Into Gold

The Israel-Based Climate Tech Startup Approaches Unicorn Status By Converting Household Waste Stream Into Materials Used in Place of Plastic

This week, I am a guest of Israel’s Foreign Ministry, learning about social impact with a delegation of content creators. I hope to share three reports from my visit this week, with future reports likely. I will not share any podcasts this week.

If it weren’t for the $170 million raised in December 2021, I’m not sure I’d have believed what UBQ’s co-CEO Jack (Tato) Bigio shared with us today.

He explained that the startup is “replacing plastics made out of oil with a material made entirely out of waste. It’s 100 percent waste.” In the process, UBQ takes unfiltered, unsorted household waste—separates and removes the metal and glass for conventional recycling—and converts it into pellets that can be used like plastic.

To be sure we understood, he says:

We turn waste, household waste—all the waste together—into one material. We're not taking the plastics and recycling them or the paper and recycling the paper. We're taking the paper, the plastic, the diaper, the cucumber, the banana peel, everything you throw—the cottage cheese with the box and the pizza with the box and the mozzarella sticking in it—which isn't recyclable, by the way—all that together!

This is so much better than turning lead into gold. Of course, municipalities pay to operate landfills—some pay a lot. As an alternative, the first large-scale operation of UBQ is now spooling up in the Netherlands, where the local government will pay handsomely to have UBQ take the waste otherwise headed for the landfill.

From there, the company’s proprietary “physical” process separates the waste into five molecular-level ingredients. Then it recombines them in a process that yields a plastic-like material in the form of pellets ready for use in manufacturing.

UBQ already has an A-list of clients, including Pepsi and Mercedes. Yes, Mercedes is putting dirty diapers and other trash—converted neatly into plastic—in its cars. McDonald’s is making serving trays for its restaurants from the UBQ material.

The process, the company says, uses a fraction of the heat of traditional plastic production and generates zero waste (apart from the metal and glass that gets recycled separately). The dust created by the process is carefully collected and fed into the system—zero waste.

The carbon difference is astounding.

A ton of PVC plastic requires emission of two tons of CO2. Jack explained that a ton of UBC material prevents almost 12 tons of CO2.

Not only does UBQ save carbon, but it also saves landfill space. On its website, UBQ boasts that its solar panels produce 100 percent of the required energy. This plastic is as green as you can imagine, magically turning garbage into gold.

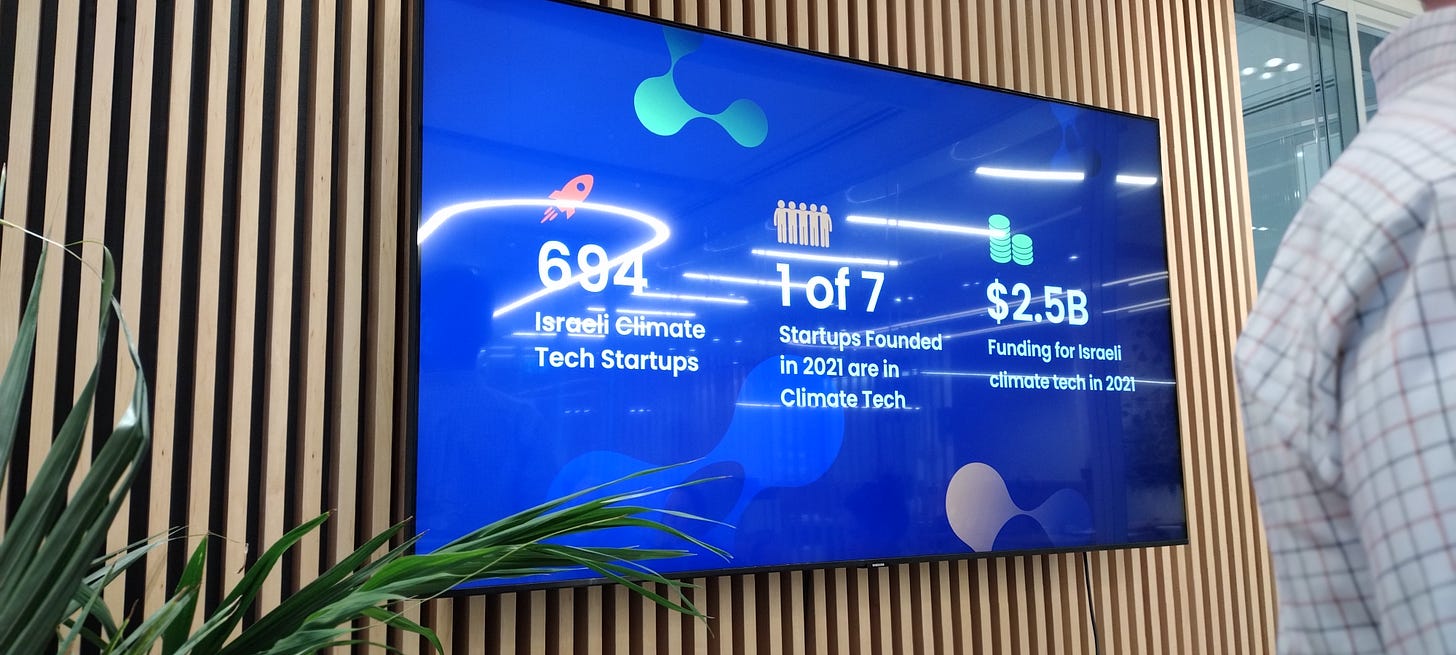

Gal Sharon, community manager for Israel’s PLANETech nonprofit that encourages and reports on the development of climate tech businesses, says UBQ is just one of almost 700 climate-friendly businesses it tracks.

Helping to reverse climate change is quickly becoming big business in Israel. The number of climate-focused startups has jumped dramatically over the past few years, Gal says.

So far, the nonprofit has identified 694 businesses in the space and says that 1/7th of 2021 startups in Israel were climate tech companies. Collectively, they raised $2.5 billion in 2021.

While technology alone can’t reverse climate change, it is exciting to see the hope we can take from entrepreneurs around the world working to profit from climate-friendly technology.